Use Video Security to Improve Workplace Safety and Compliance

Workplace accidents and injuries are an unfortunate reality across many U.S. industries. In manufacturing, warehousing, mining, and other industrial environments, risk is often built into the work itself: fast-paced operations, heavy machinery, repetitive tasks, and physically demanding conditions all increase the likelihood of incidents.

Other risks stem from operational issues: inconsistent enforcement of safety protocols, poorly designed workflows, inadequate training, missing machine guards, or simple fatigue that develops over long shifts. Over time, these risks compound, impacting not only safety but productivity, compliance, and employee morale.

When used correctly, video security systems play a meaningful role in identifying, reducing, and managing these risks, while also supporting compliance and long-term operational improvement.

Why Workplace Safety Still Matters: Financially and Operationally

Strong safety practices aren’t just about avoiding injuries. They directly affect a company’s bottom line.

Better safety practices typically lead to:

- Fewer workers’ compensation claims

- Reduced OSHA penalties

- Less downtime from injured employees

- Lower liability exposure

- Improved productivity

- Higher employee confidence and morale

Employees who feel safe at work are more focused, more engaged, and more likely to stay—especially in today’s tight labor market.

Video Surveillance in Industrial Operations

Workplace injuries remain an important concern across U.S. industries. According to the latest data published by OSHA and the U.S. Department of Labor, employers reported more than 1.3 million workplace injuries and illnesses in 2024, with a range of injury types including lost-time cases, respiratory conditions, and other work-related illnesses. Recognizing where injuries occur and what contributes to them is a key step in improving safety protocols and preventing future harm.

Video security footage can provide objective visibility into workplace conditions, helping identify hazards, unsafe behaviors, or operational inefficiencies that contribute to injuries. It’s not a replacement for engineering controls or safety training, but it amplifies situational awareness for safety and operations teams.

How Video Security Improves Safety Outcomes

When deployed thoughtfully, video security helps organizations move from reactive to proactive safety management.

Video footage can help:

- Identify where speed or workflow contributes to fatigue or unsafe behavior

- Reveal bottlenecks or poor operational design

- Highlight where safety protocols aren’t being followed consistently

- Pinpoint areas that require additional training or supervision

- Provide objective insight instead of relying solely on anecdotal reports

Once risks are visible, operations and safety teams can make informed changes, whether that means redesigning a process, improving training, or reinforcing safety procedures.

Using Video Footage for Training and Accountability

Video footage is also a powerful tool for:

- Safety training

- Incident review

- Root-cause analysis

- Reinforcing best practices

When employees understand why a safety rule exists and can see how incidents occur, they’re more likely to comply. At the same time, management gains clarity on whether safety failures are systemic or behavioral, allowing for fair and appropriate responses.

Video Security and OSHA Compliance

OSHA compliance is often viewed as a regulatory burden, but the underlying goal is straightforward: preventing unnecessary harm.

Most reputable employers want to provide a safe working environment. When violations occur, they are often unintentional, caused by oversight, inconsistent enforcement, or operational drift over time.

Video surveillance can help businesses:

- Monitor compliance with safety procedures

- Demonstrate compliance after an incident

- Identify hazards before OSHA does

- Support internal audits and corrective actions

Of course, video can be used against an employer if violations are present, but for organizations committed to safety, it’s far more often a protective tool than a liability.

Common OSHA Issues Video Surveillance Can Help Identify

Rather than relying on outdated regional citation lists, it’s more useful to look at the most commonly cited OSHA safety violations nationwide as a gauge of persistent workplace risks. According to OSHA’s most recent Top 10 Most Frequently Cited Standards (Fiscal Year 2024), businesses are repeatedly cited for hazards that video security can help reveal or monitor, including:

- Machine guarding deficiencies, where moving parts are not properly guarded to prevent contact

- Fall protection violations

- Hazard communication failures

- Lockout/tagout control of hazardous energy violations

Machine guarding alone accounted for well over a thousand violations in 2024, showing that unsafe machinery conditions remain widespread.

Video footage can be invaluable in identifying whether guards were removed, safety procedures bypassed, or hazardous practices are occurring and help you correct issues before injuries or fines occur.

Modern Video Security Makes Monitoring More Practical in 2025

Today’s IP video systems are far more capable than those installed a decade ago.

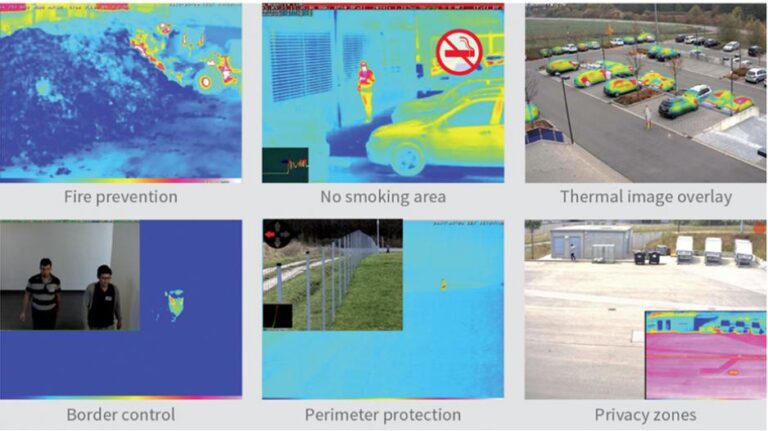

Modern systems can:

- Run continuously with minimal maintenance

- Use AI to detect unsafe behavior or presence in restricted zones

- Reduce false alerts compared to motion-only systems

- Be monitored remotely for uptime and performance

- Provide clear, time-stamped evidence when incidents occur

This makes video security more scalable and less intrusive, especially in large or multi-site industrial operations.

Safety, Compliance, and Long-Term Value

Organizations that take a proactive approach to safety and compliance tend to recognize the value of video security not just as surveillance, but as an operational tool.

It’s no coincidence that safety managers, HR teams, and compliance officers are often the driving force behind:

- New camera installations

- Upgrades from early-generation systems

- Expanded coverage in high-risk areas

The goal isn’t constant monitoring of employees; it’s risk reduction, accountability, and continuous improvement.

How Vulcan Helps

Vulcan Security Systems designs and supports IP video systems for industrial and commercial environments throughout north and central Alabama.

We work with manufacturers, warehouses, mines, and other high-risk operations to:

- Identify where video adds real safety value

- Design systems that support compliance, not micromanagement

- Ensure cameras stay online and reliable through proactive monitoring

- Provide clear, usable footage when incidents occur

If you’re evaluating how video security can support workplace safety and compliance at your facility, contact Vulcan Security Systems in Birmingham for a free needs assessment.

We’ll help you understand where video makes sense and where it doesn’t, so you can make informed, practical decisions.