Thermal Cameras for Predictive Equipment Maintenance

Machine uptime and consistent quality control remain two of the biggest drivers of profitability in manufacturing. Over the last several years, thermal imaging has shifted from a niche diagnostic tool to a frontline technology used across industrial environments to predict failures, prevent downtime, and strengthen compliance.

If you’re exploring whether thermal video can support your operation, this article explains what thermal cameras do, how they work, and the real applications we see in the field today.

This guide is written for plant managers, maintenance professionals, reliability engineers, and safety teams who want a clear, practical explanation, not a sales pitch.

What Thermal Cameras Are and Why Industrial Facilities Use Them

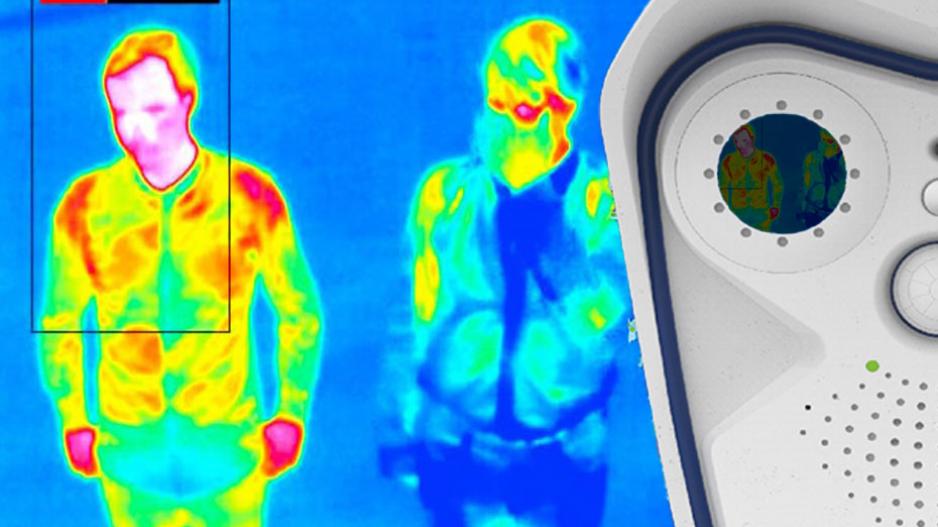

Thermal cameras, often called infrared (IR) cameras, detect and visualize heat rather than visible light. Every object emits a thermal signature. By reading these signatures, high-sensitivity sensors can identify abnormal temperature patterns that signal equipment issues long before a failure occurs.

Across modern industry, adoption continues to rise. Today, thermal cameras are being deployed in:

- Manufacturing

- Data centers

- Biotech and pharmaceutical production

- Food and beverage processing

- Materials handling

- Mining and energy

- Veterinary and agricultural facilities

The reason is simple. Thermal imaging gives operators a non-contact, always-on view of conditions that were previously invisible without scheduled manual inspections.

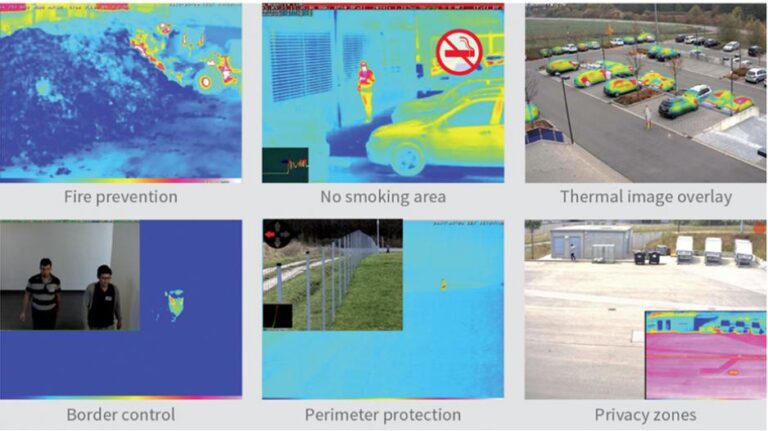

Two Examples of Less-Obvious but High-Value Applications

1. Quality Control for High-Temperature Materials

In processes like glass bottle production, materials must reach precise temperatures during forming. A thermal camera verifies the heat profile in real time. If the temperature drifts from spec, operators can correct it immediately: reducing scrap, energy waste, and product defects.

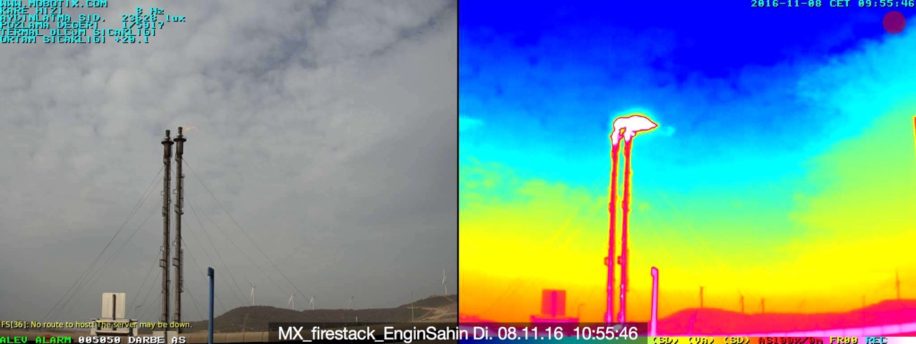

2. Flare Stack Monitoring for EPA Compliance

Flare stacks sometimes burn with a clear flame that optical cameras can’t reliably detect. Thermal imaging ensures you always know whether the flame or pilot light is lit. This is essential for environmental compliance and safe plant operation.

How Modern Thermal Cameras Work

Thermal technology has improved dramatically since this article was first written. The thermal sensors in cameras like the MOBOTIX M73 series are now capable of detecting temperature differences as small as 0.05°C (0.09°F) across a typical industrial range of –40°C to 550°C (–40°F to 1022°F).

This type of sensitivity allows thermal cameras to:

- Monitor production lines for uniform heat distribution

- Identify overheating or failing equipment

- Detect leaks, insulation failures, or electrical anomalies

- Provide documentation for compliance and audits

- Alert staff before a dangerous temperature threshold is reached

Most importantly, improvements in processing mean thermal cameras now handle these tasks with more accuracy and fewer false positives than even five years ago.

Where Thermal Cameras Fit Into Predictive Maintenance Programs

Thermal imaging has become a non-negotiable tool for predictive maintenance across industries. Cameras can identify deviations from normal operating temperatures, often the earliest indicator of:

- Bearing failures

- Motor overload

- Electrical faults

- Conveyor friction

- Pump cavitation

- Belt misalignment

- Hydraulic and pneumatic system issues

Because the camera is always monitoring, operators no longer rely solely on periodic route-based inspections. Instead, they receive immediate alerts if a component begins overheating or cooling unexpectedly.

This shift from reactive to predictive maintenance reduces:

- Unscheduled downtime

- Equipment replacement costs

- Safety incidents

- Energy waste

Automated Alerts and Line Shutdowns

One advantage thermal cameras offer compared to handheld temperature tools is automation.

Cameras can be programmed to:

- Send temperature alerts to supervisors

- Notify maintenance teams directly

- Trigger alarms

- Shut down equipment automatically if temperatures exceed safe limits

This reduces the lag between detection and human response, a gap that often causes equipment damage or product loss.

In many facilities, thermal cameras now integrate directly with existing platforms such as:

Mobotix, in particular, continues to support deep integration with industrial control systems. As Mark Heintzman, Business Development Manager at Mobotix, explains, “Mobotix thermal cameras can monitor up to 20 points in the field of view.” That level of detail allows precision monitoring without the cost of installing dozens of sensors.

Remote Monitoring for Safety, Production, and Maintenance

Thermal cameras support the same remote-access capabilities as IP video systems. For many facilities, this is now a standard requirement, especially when monitoring:

- Flare stacks

- Kilns and furnaces

- High-voltage rooms

- Hazardous environments

- 24/7 production lines

Remote visibility means safety teams, operators, and maintenance professionals can check conditions at any time, without needing to physically access dangerous or sensitive areas.

In situations like flare stack compliance, this is essential. Even if the visible flame disappears, the thermal signature remains readable, ensuring continuous monitoring and documentation.

Why More Industrial Facilities Are Adding Thermal Cameras in 2025

Since the original publication of this article in 2019, interest in thermal imaging has accelerated. In the last year alone, multiple Vulcan clients have expanded their video systems specifically to include thermal cameras. The reasons are consistent:

- Predictive maintenance programs are maturing

- Downtime is more costly than ever

- Regulatory pressure continues to grow

- Thermal imaging now integrates smoothly with industrial control systems

- Camera costs have decreased while capability increased

Across industries, leadership teams want fewer surprises. Thermal imaging is one of the most efficient ways to achieve this.

If You’re Evaluating Thermal Cameras for Your Facility

If you’re considering thermal imaging for predictive maintenance, quality control, or compliance, we can help you determine where the technology will deliver the greatest value.

We’re currently supporting several industrial clients upgrading their systems to include thermal cameras as part of broader operational improvements. If you have questions or want to see what thermal imaging looks like in a real production environment, we’re happy to walk through examples and best practices.

Thermal cameras aren’t just a security tool. They’re an operational asset that helps protect uptime, equipment health, and product quality.